Tungsten Carbide Burs

- Provides smooth operation and maximum tool control

- Double cut (Alternate cut) is the most popular bur in ferrous applications

- Manufactured with cuts made on the left and right spirals to produce a finer finish on material resulting in smaller chips and slivers

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Metal

Ferrous Metals (iron, steel, welds, cast iron, etc.)

Stainless

Stainless steel and high tensile alloys

- More open, aggressive cut to avoid loading on softer materials

- Easy chip flow with little or no clogging

- Provides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Aluminum

Non-ferrous metals (aluminum, copper, brass, etc)

- More durable design for additional resistance to chipping and less prone to filling with chips

- Substantially reduces production cost by removing more material per hour vs. standard carbide burs

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Metal

Ferrous Metals (iron, steel, welds, cast iron, etc.)

Stainless

Stainless steel and high tensile alloys

- Provides smooth operation and maximum tool control

- Double cut (Alternate cut) is the most popular bur in ferrous applications

- Manufactured with cuts made on the left and right spirals to produce a finer finish on material resulting in smaller chips and slivers

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Metal

Ferrous Metals (iron, steel, welds, cast iron, etc.)

Stainless

Stainless steel and high tensile alloys

- More open, aggressive cut to avoid loading on softer materials

- Easy chip flow with little or no clogging

- Provides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Aluminum

Non-ferrous metals (aluminum, copper, brass, etc)

- Provides smooth operation and maximum tool control

- Double cut (Alternate cut) is the most popular bur in ferrous applications

- Manufactured with cuts made on the left and right spirals to produce a finer finish on material resulting in smaller chips and slivers

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Metal

Ferrous Metals (iron, steel, welds, cast iron, etc.)

Stainless

Stainless steel and high tensile alloys

- More open, aggressive cut to avoid loading on softer materials

- Easy chip flow with little or no clogging

- Provides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.

- Excellent for confined or hard-to-reach areas

- Use for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Aluminum

Non-ferrous metals (aluminum, copper, brass, etc)

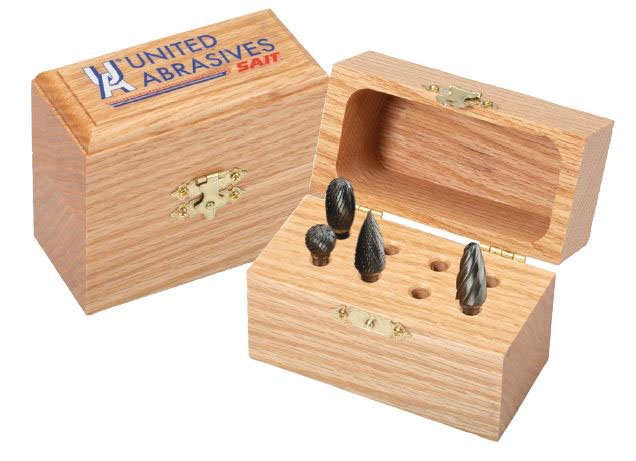

- Wooden display case holds up to 8 burs