The following chart is an example of the ANSI standard marking system for identifying grinding wheels and other bonded abrasives.

| A | 24 | R | BF |

|---|---|---|---|

| Primary grain used to make the wheel | Size of the abrasive grain | Hardness of the bond | Type of bond used |

| A = Aluminum Oxide C = Silicon Carbide Z = Alumina Zirconium SG = Seeded Gel | CoarseMediumFineVery Fine 8 30 70 220 10 36 80 240 12 46 90 280 14 54 100 320 16 60 120 400 20 150 500 24 180 600 | Soft Medium Hard  A N R T Z | B = Resinoid BF = Resinoid Reinforced E = Shellac O = Oxychloride R = Rubber RF = Rubber Reinforced S = Silicate V = Vitrified |

Wheel Configurations

Bonded abrasive wheels have different configurations depending upon the tool the wheel is used on and the desired end result.

Below are the configurations that a wheel can have:

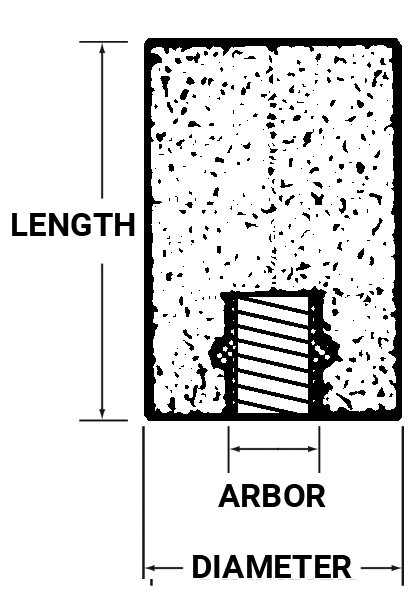

Type 1 / Type 41 –Straight Wheel

Type 27 /Type 42 –Depressed Center Wheel

Type 28 – Saucer-Shaped Wheel

Type 29 – Flexible Wheel

Type 11 – Flaring Cup Wheel

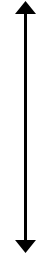

Type 16 – Rounded Cone

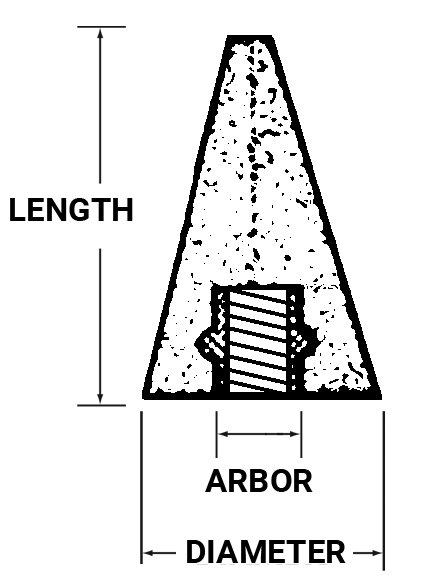

Type 17 – Straight-Sided Cone