What is a Bonded Abrasive?

A resin bonded abrasive is a grinding or cutting tool composed of abrasive grains which are held tightly together by a bonding agent and typically reinforced with a woven material. Within the bonded abrasives category are grinding and cutting wheels, as well as “stones” in a variety of shapes and sizes.

Main Components of Resinoid Bonded Abrasives

Abrasive Grains

Abrasive grains, sometimes referred to as grit, are particles of man-made compounds. The chemical structure of the grains determines the physical properties such as the shape and sharpness of each particle along with its hardness and friability (the propensity to break down). Common grain types used in making bonded abrasives include:

- A – Aluminum Oxide: A tough blocky shaped grain used for cutting metals and other high tensile strength materials without excessive fracturing

- C – Silicon Carbide: A very hard and very sharp abrasive suited for non-metallic materials such as concrete

- Z – Zirconium: A very fine, dense crystalline grain which can be used for rugged stock removal

- SG – Ceramic: A unique ceramic aluminum oxide that is two or three times tougher than standard aluminum oxide

Bonding Agent

The bonding agent that holds the grains together determines the resistance of the wheel.

Reinforcement

The reinforcement material provides strength to operate the abrasive product at the marked maximum RPMs and to withstand lateral pressure that is applied during use. This critical element, unseen to the naked eye, determines the structural strength of the product.

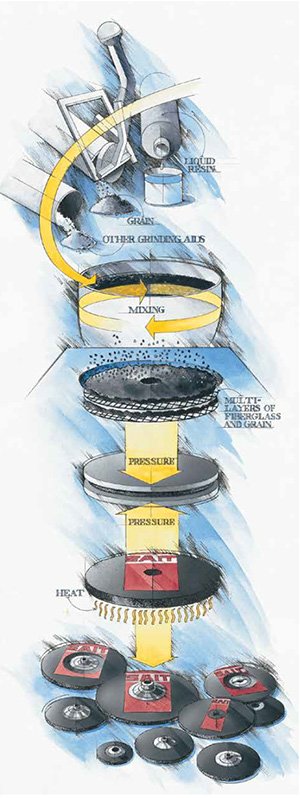

Combining the Components

During the manufacturing process, these three components are combined to form an abrasive tool. The grains and bonding agents are measured, combined, and then pressed in an automated hydraulic press.

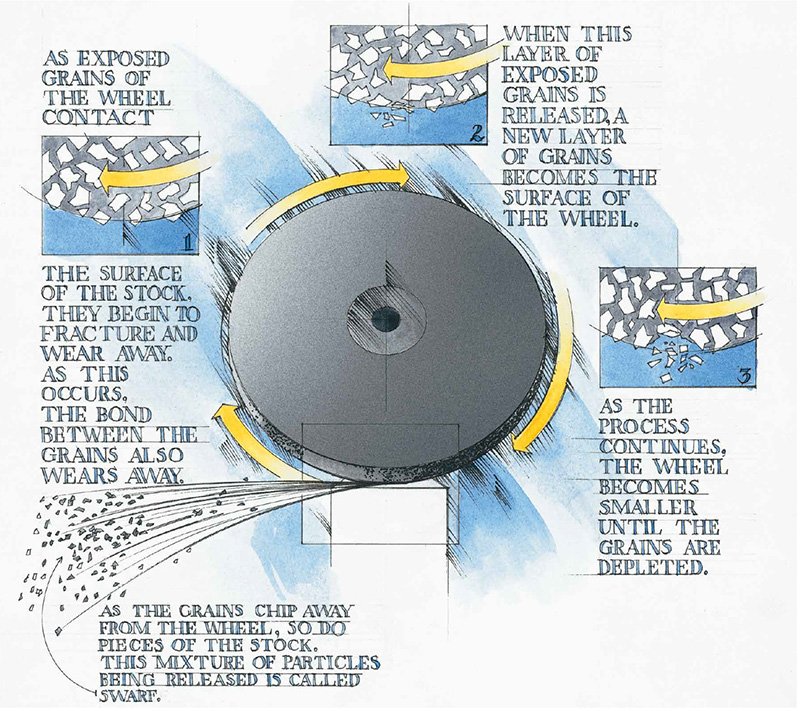

How a Wheel Works

Common Occurrences With Grinding/Cutting Applications

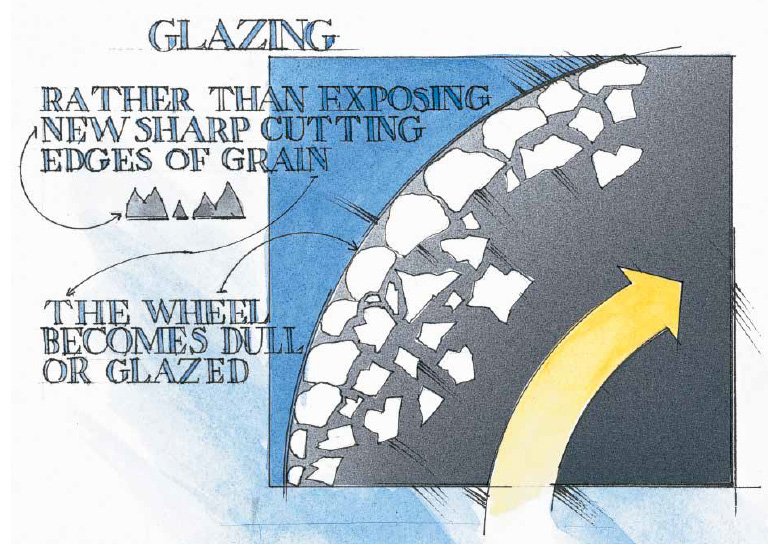

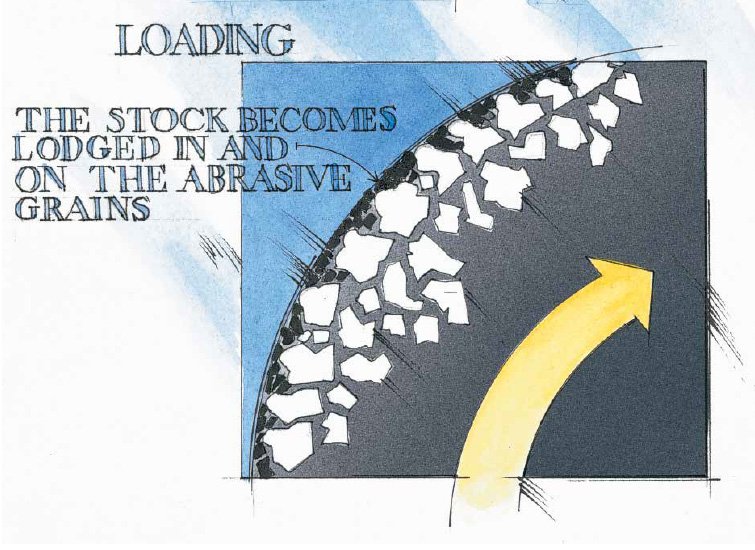

As a wheel is grinding and/or cutting, some situations may occur with the application such as glazing or loading. Here is a description of each of these occurrences and some possible solutions.

Solutions to Glazing

- Dress the wheel for a temporary solution

- Use a softer bond and/or coarser grit wheel

Solutions to Loading

- Dress the wheel for a temporary solution

- Use the correct wheel for the application