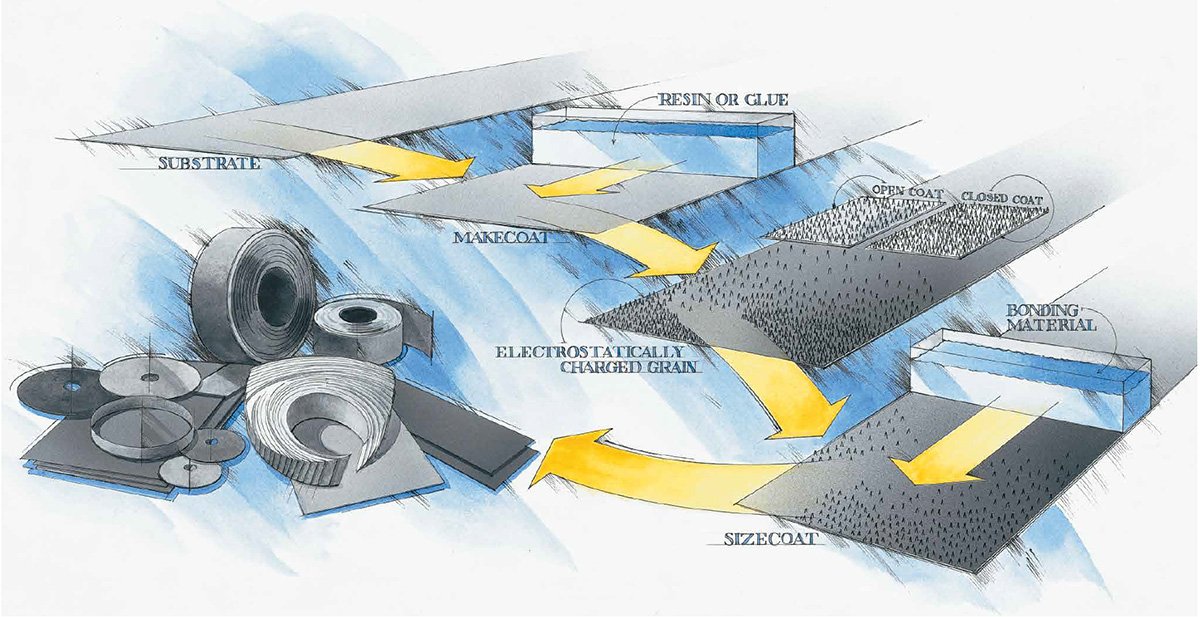

What is a Coated Abrasive?

A coated abrasive is a product that consists of a thin layer of abrasive grain attached to a substrate such as paper, cloth, etc. Coated abrasives come in a variety of forms such as sheets, discs, rolls, specialties, or belts.

Components of Coated Abrasives

Abrasive Grains

Coated abrasives are manufactured using abrasive grains; the most common are aluminum oxide, zirconium, ceramic, silicon carbide and garnet. The crude grains are crushed and separated into sizes, called grit sizes, using calibrated screens. Grits range from 12 (very coarse) to 1200 (very fine). Once the grains are separated into sizes, they are attached to a backing material using various bond techniques. Below are descriptions of the most common abrasive grains:

Ceramic:

A high performance, man-made abrasive material. Very uniform, high density grain structure is extremely durable and self sharpening for longer life and cooler cut. Excels on tough to grind materials.

Aluminum Oxide:

A tough, blocky shaped, man-made grain used for high speed grinding and finishing of metals, wood, and other high tensile strength materials without excessive fracturing or shedding. Wherever the ability to resist fracturing is the main consideration, aluminum oxide will outperform all other coated abrasive grains.

Zirconium:

A very fine, dense, man-made crystalline grain which can be used for aggressive stock removal. Zirconium is a very dense material with a unique self-sharpening characteristic which gives it long life on heavy stock removal operations.

Silicon Carbide:

A very hard, very sharp, man-made abrasive suited for non-ferrous materials and non-metallic materials such as concrete, marble and glass. A very friable grain, silicon carbide cuts faster under light pressure than any other grain used in coated abrasives.

Garnet:

Garnet is made of natural aluminum oxide which is a relatively sharp, but very weak bonding structure. Very inconsistent when compared to synthetics. It is used primarily in woodworking as garnet dulls too quickly to be used in metalworking.

Backing Materials (Substrates)

Below are the four major types of backing materials:

Paper

Specialized technical papers are used as substrates for coated abrasives. They are identified by letters representing weight and flexibility:

“A” and “B” weights are light weight and highly flexible. “C”, “D”, “E”, “F” weights are medium to heavy weight for more strength and less flexibility.

Cloth

Cloth backings are more durable than paper backings. There are several types of cloth backings: cotton (ie: Egyptian), polyester and polyester-cotton blends. Cloth backings are identified by weight and flexibility: “F” weight (J-Flex) is light and highly flexible. This lighter weight is suitable for cleaning, finishing, and polishing. “J” weight (Jeans) is highly flexible and suitable for cleaning, finishing, and polishing of contour surfaces. “X” weight (Drills) is medium to heavy weight for more strength and durability. It has low flexibility suitable for grinding, deburring and finishing. “H” (Heavy Duty) is a heavier weight than “X” weight. It has low flexibility and is suitable for heavy duty grinding and deburring applications. Excellent edge stability.

Fiber

Fiber backing is a tough vulcanized material made from rag stock. This backing is usually used for abrasive fiber discs.

Combination

Combination backing is laminated paper and cloth, and is very sturdy and shock resistant. Combination backings typically are used for a wide range of grits and mounting techniques.

Other Backing Materials

There are also a variety of other substrates such as nylon fiber or screens that can be coated for special applications. Non-woven nylon impregnated with abrasive grain is another substrate that can be used for cleaning, polishing, or blending.

Storage and Handling

Incorrect storage of coated abrasives will significantly affect performance. All types of backings are susceptible to variations in temperature and humidity during storage:

- Keep stockroom at constant levels of humidity (35-50%) and temperature (60-80° F)

- Keep cartons away from damp or cold walls and floors where they may absorb moisture

- Store coated abrasives away from any heat source

- Keep products in original packages for easy handling and stacking

- Flap wheels removed from the original packaging should be spread out on a clean shelf, always placed face down, never resting on edge

- Fiber discs removed from the original packaging should be stored in a suitable disc holder and kept under pressure

- Store bulk rolls flat on shelves or pallets, not on edge

- Belts removed from packing case should be rolled up and stood on edge on a clean shelf. They may be draped over a large cylinder but never hang a belt from a nail or peg (the backing will crease and the abrasive coat will crack)

- Precondition the coated abrasive products in a humidity and temperature controlled environment before use for maximum efficiency