Carbide Grain Structure

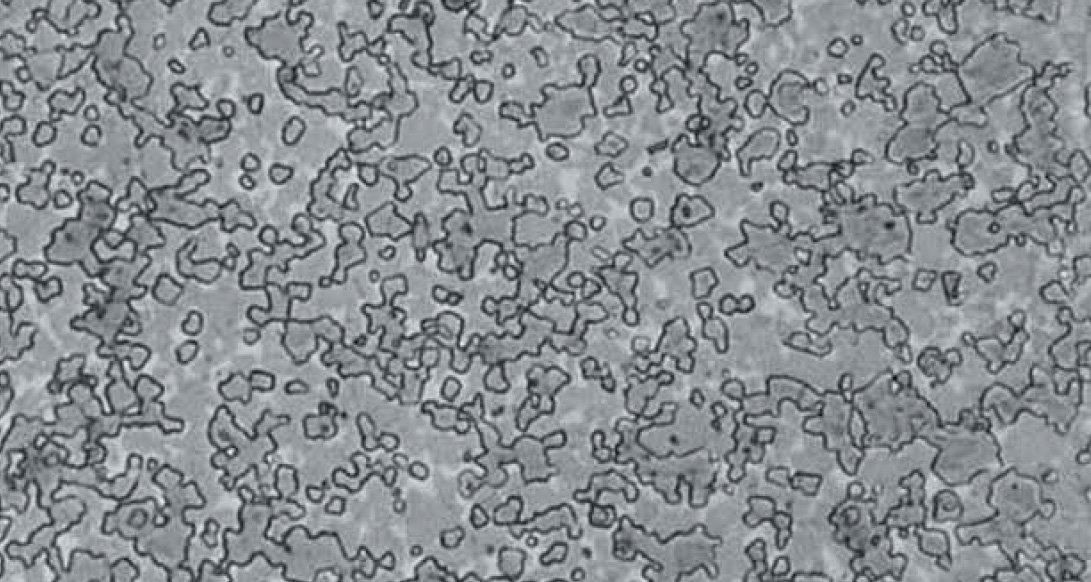

SAIT Carbide Matrix

- Consistent size of carbide grains.

- More carbide per tooth as grains are smaller.

- Smaller grain = harder tooth, more durability.

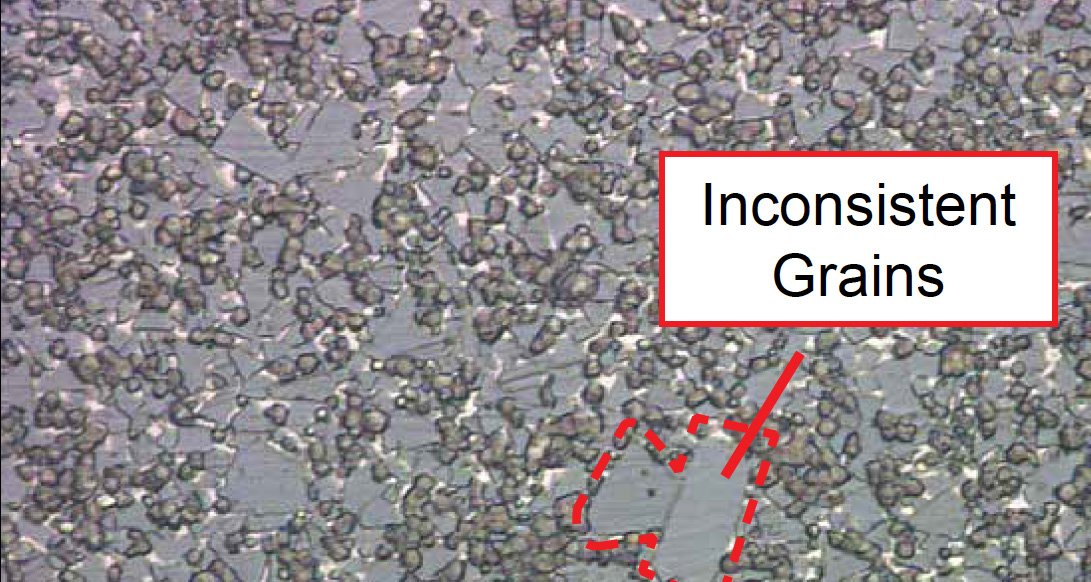

Competitor Carbide Matrix

- Very inconsistent size of carbide grains.

- Less life due to larger grain sizes.

Tooth Configuration

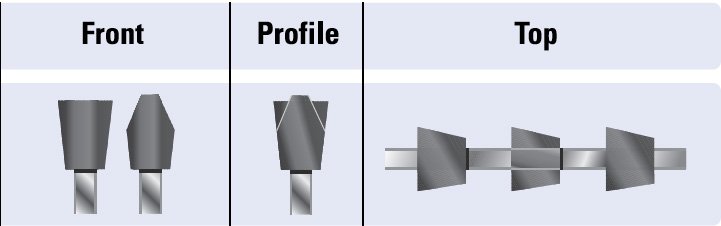

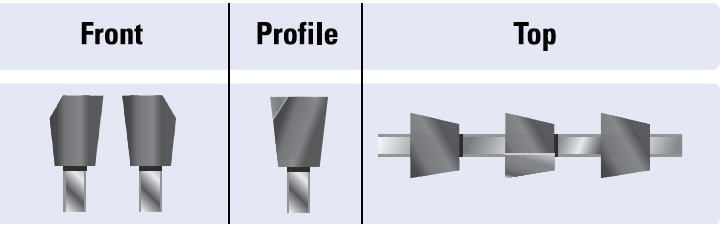

Triple Chip Grind (TCG):

- FEATURE: Maximizes blade life by reducing the size of the metal chips that are produced during the cutting operations. Also provides maximum tooth strength for longer life.

- BENEFIT: Cleaner and cooler cuts and less stress on material being cut.

- WHERE USED: Steelworker® (all sizes), 7-1/4” Stainless, 8”, 10” and 12” Aluminum blades

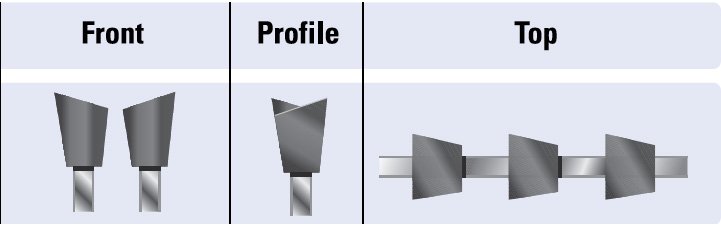

Alternate Top Bevel (ATB)

- FEATURE: A multi-purpose grind that allows for durable, long life as well as productive work across a wide range of materials.

- BENEFIT: Clean, easy cutting without binding in the material.

- WHERE USED: 6-1/2” and 7-1/4” TMX, and 14” Aluminum Blades

Modified Triple Chip Grind (MTCG):

- FEATURE: Excels at reducing chip size for more effective cutting of material. Also improves cutting tooth durability.

- BENEFIT: Lower heat build-up and less blade stress while cutting.

- WHERE USED: 12” and 14” TMX and 14” Stainless Steel Blades.

Blade Operation Tips

- Be sure to mount the blade with the rotational arrow positioned the same direction as the tool rotates

- Follow circular saw manufacturer’s warnings and instruction manual

- Check blade prior to use for any visible cracks, loose or missing teeth, etc. and change blade if found

- Use blade only on recommended material

- Mount blade between designated sides of blade washers matching arbor size and shape

- Always wear ANSI-approved eye protection and proper protective equipment

- Always wear gloves

- Adjust foot-plate of the saw to proper depth (check circular saw manual – 3 teeth exposed below material surface is a common rule of thumb)

- Always work in a clean and unobstructed work environment

- Never operate saw without working blade guard

- Do not use excessive pressure when cutting (this causes the blade to wear prematurely)

- Tighten blade bolt as instructed by saw manufacturer