Mmi Application: Grinding

SAIT GF Grind & Finish Flap Discs

Combines coated and non-woven abrasives which allows you to "Grind & Finish" with one product reducing time and labor Cushioned grinding effect allows for effortless blending and finishing of contoured work pieces Aluminum oxide specifications available in coarse, medium, and very fine Ceramic specification (High Performance) available in 40 grit and 60 grit - provides exceptionally long life

Challenger 3™ Ceramic – Type 29

Semi-Flexible Grind and blend welds in one step Open pattern on wheel for cool grinding and blending Contaminant Free - Safe for use in the nuclear industry Requires no backing pad

Green Silicon Carbide Bench Wheel

Green silicon carbide grainExtremely sharp grain for faster, burr-free cuttingUse on carbide tipped tools, cast iron

Aluminum Oxide Bench Wheel

Aluminum oxide grainGeneral purposeFor sharpening tools and light stock removal

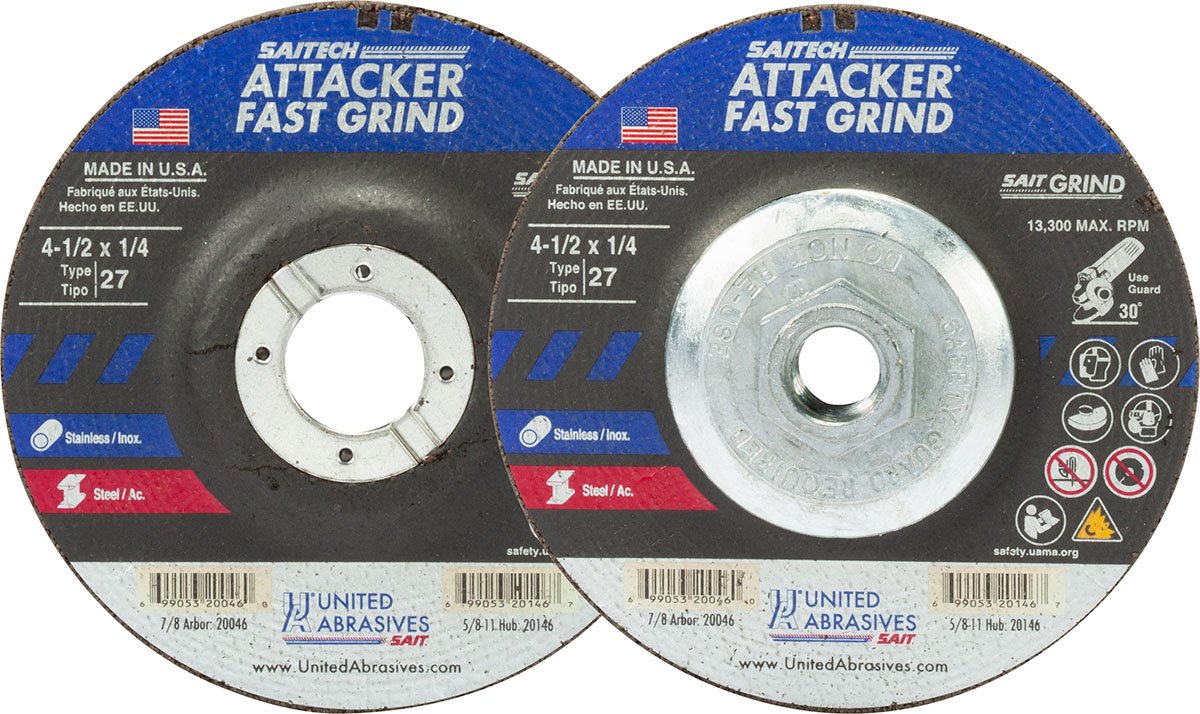

Saitech Attacker ®

Soft bond for extremely fast stock removal on hard metals with minimal pressure High performance, ceramic aluminum oxide grain, is designed to outlast standard aluminum oxide wheels Very uniform, high density grain structure is extremely durable and self sharpening for long life and cooler cut Type 27

Sait Z-Tech™ Z24R

Tough zirconium grain High performance grinding for the toughest applications Type 27

6″ Length Shank Non-ferrous (Aluminum Cut) Carbide Burs

More open aggressive cut to avoid loading on softer materialsThis design provides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.Easy chip flow with little or no cloggingExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

6″ Length Shank Carbide Burs

Double cut or Alternate cut is the most popular bur in ferrous applicationsManufactured with cuts made on the left and right spirals, this design produces a finer finish on material producing smaller chips and sliversThe double cut offers much smoother operation and greater tool controlExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Heavy Duty Carbide Burs

Bear Cut - Substantially cuts production costs by removing more material per hour vs. standard carbide bursMore durable due to depth of teethMore resistant to chipping and less prone to filling with chipsExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Non-ferrous (Aluminum Cut) Carbide Burs

More open aggressive cut to avoid loading on softer materialsThis design provides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.Easy chip flow with little or no cloggingExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Double Cut (Alternate Cut) Carbide Burs

Double cut or Alternate cut is the most popular bur in ferrous applicationsManufactured with cuts made on the left and right spirals, this design produces a finer finish on material producing smaller chips and sliversThe double cut offers much smoother operation and greater tool controlExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Single Row Turbo Diamond Cups

Aggressive cut for maximum stock removal and smooth finish For use on a wide range of masonry building materials (brick, blocks, pavers, etc.) and concrete tiles (roofing, etc.)

Double Row Diamond Cups

Fast Stock removal and long life while delivering a smooth finish For use on a wide range of masonry building materials (brick, blocks, pavers, etc.) and concrete tiles (roofing, etc.)

Single Row Diamond Cups

Extremely fast stock removal For use on a wide range of masonry building materials (brick, blocks, pavers, etc.) and concrete tiles (roofing, etc.)

Challenger 3™ – Type 29

Semi-Flexible Grind and blend welds in one step Open pattern on wheel for cool grinding and blending Contaminant Free - Safe for use in the nuclear industry Requires no backing pad

Subscribe

Get product news and tips straight to your inbox