Mmi Application: Finishing

Buffing Discs

Premium quality buffing material Designed for final cosmetic finishing Available in Hook & Loop and Sait-Lok™-R A slower speed achieves a better finish and reduces heat

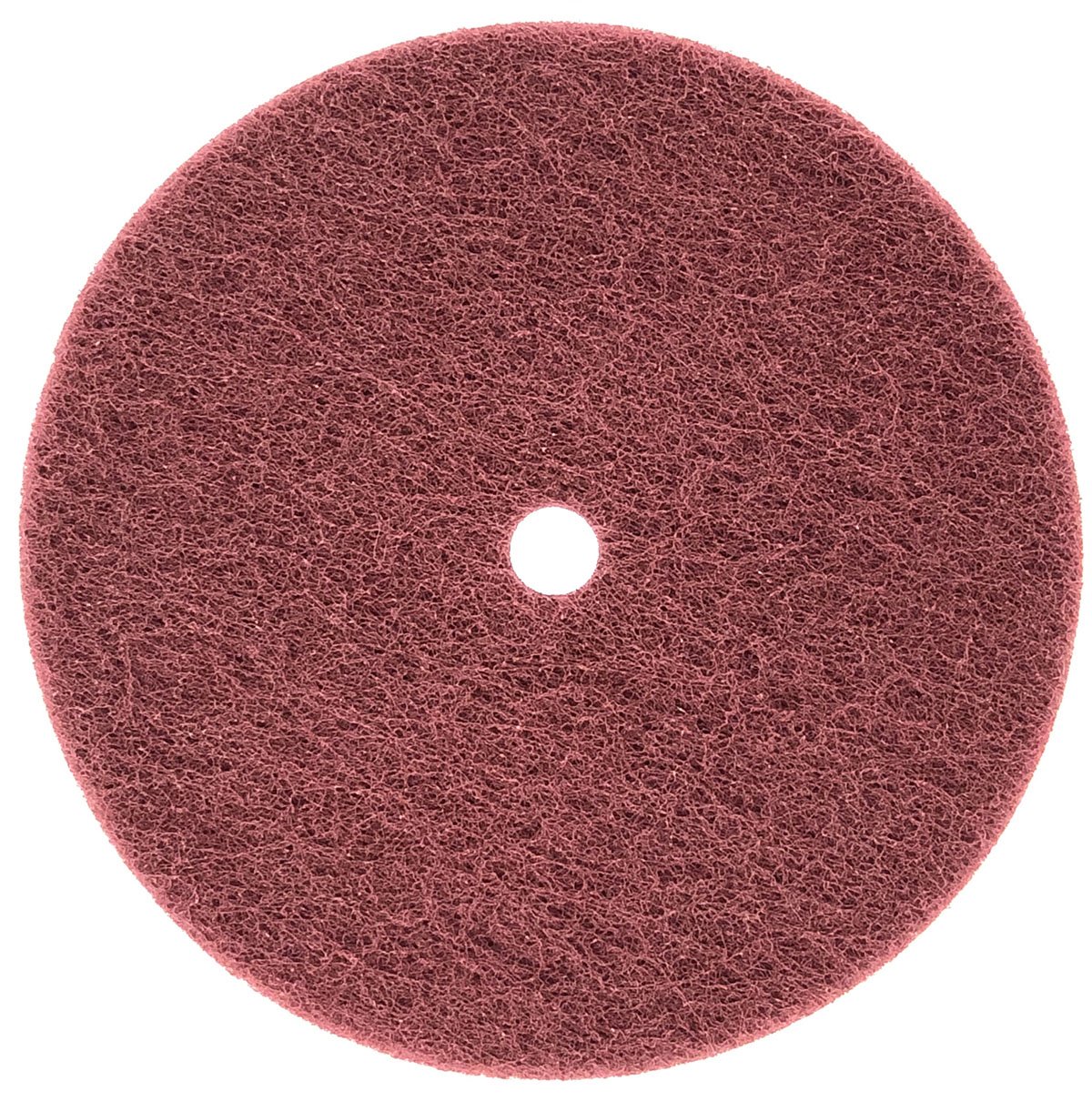

Sand-Light™ Blending Discs with Arbor Hole

Arbor hole for easy mounting to grinder shaft For minor finishing and blending applications Less aggressive cutting than traditional surface conditioning discs Great for final finishing prior to buffing with compounds Use the slowest speed possible for optimum results

Hook & Loop Sand-Light™ Blending Discs

Hook & Loop fastening system allows for quick changes and less downtime For minor finishing and blending applications Less aggressive cutting than traditional surface conditioning discs Great for final finishing prior to buffing with compounds Use the slowest speed possible for optimum results

Sait-Lok™ Sand-Light™ Blending Discs

Nylon attachment on disc ensures a secure fit to the backing pad For minor finishing and blending applications Less aggressive cutting than traditional surface conditioning discs Great for final finishing prior to buffing with compounds Use the slowest speed possible for optimum results

Non-Woven Belts

Non-woven synthetic fiber impregnated with abrasive grain for surface conditioning without damage to or removal of base material. Resists loading and heat build-up Offered in very narrow widths for use on tight radii and hard to reach applications Flexible yet extra durable splice method for resistance to breaking or cracking under severe stress

Hand Pads

Non-woven synthetic fiber impregnated with abrasive grain for surface conditioning without damage to or removal of base material. Resists loading and build-up Wet/dry construction for use in a wide range of applications Available in a variety of grades from heavy duty to polishing applications Reusable and long lasting design for economical use Box label UPC bar coded for easy identification and inventory maintenance

Stainless Steel

For use on portable power toolsExcellent for use in cleaning and finishing recessed areas or pipesKnot Wire: Provides aggressive cutting actionCircular Flared: Excellent for side cleaning actionCrimped Wire: For high flexibility

Carbon Steel

For use on portable power toolsExcellent for use in cleaning and finishing recessed areas or pipesKnot Wire: Provides aggressive cutting actionCircular Flared: Excellent for side cleaning actionCrimped Wire: For high flexibility

Heavy Duty Carbide Burs

More durable design for additional resistance to chipping and less prone to filling with chipsSubstantially reduces production cost by removing more material per hour vs. standard carbide bursExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Single Cut (Non-ferrous) Carbide Burs

More open, aggressive cut to avoid loading on softer materialsEasy chip flow with little or no cloggingProvides outstanding stock removal on aluminum, magnesium, copper, soft steel, brass, zinc alloys, hard rubber, most plastics, and non-ferrous metals.Excellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Double Cut (Alternate Cut) Carbide Burs

Provides smooth operation and maximum tool controlDouble cut (Alternate cut) is the most popular bur in ferrous applicationsManufactured with cuts made on the left and right spirals to produce a finer finish on material resulting in smaller chips and sliversExcellent for confined or hard-to-reach areasUse for deburring, finishing, shaping and enlarging holes, removing welds, and smoothing castings

Cotton Fiber Wheels

Multiple layers of cotton impregnated with abrasive grain and special bonding agents allow for the coolest blending and finishing wheels Special cotton formula minimizes loading on soft, non-ferrous metals like aluminum

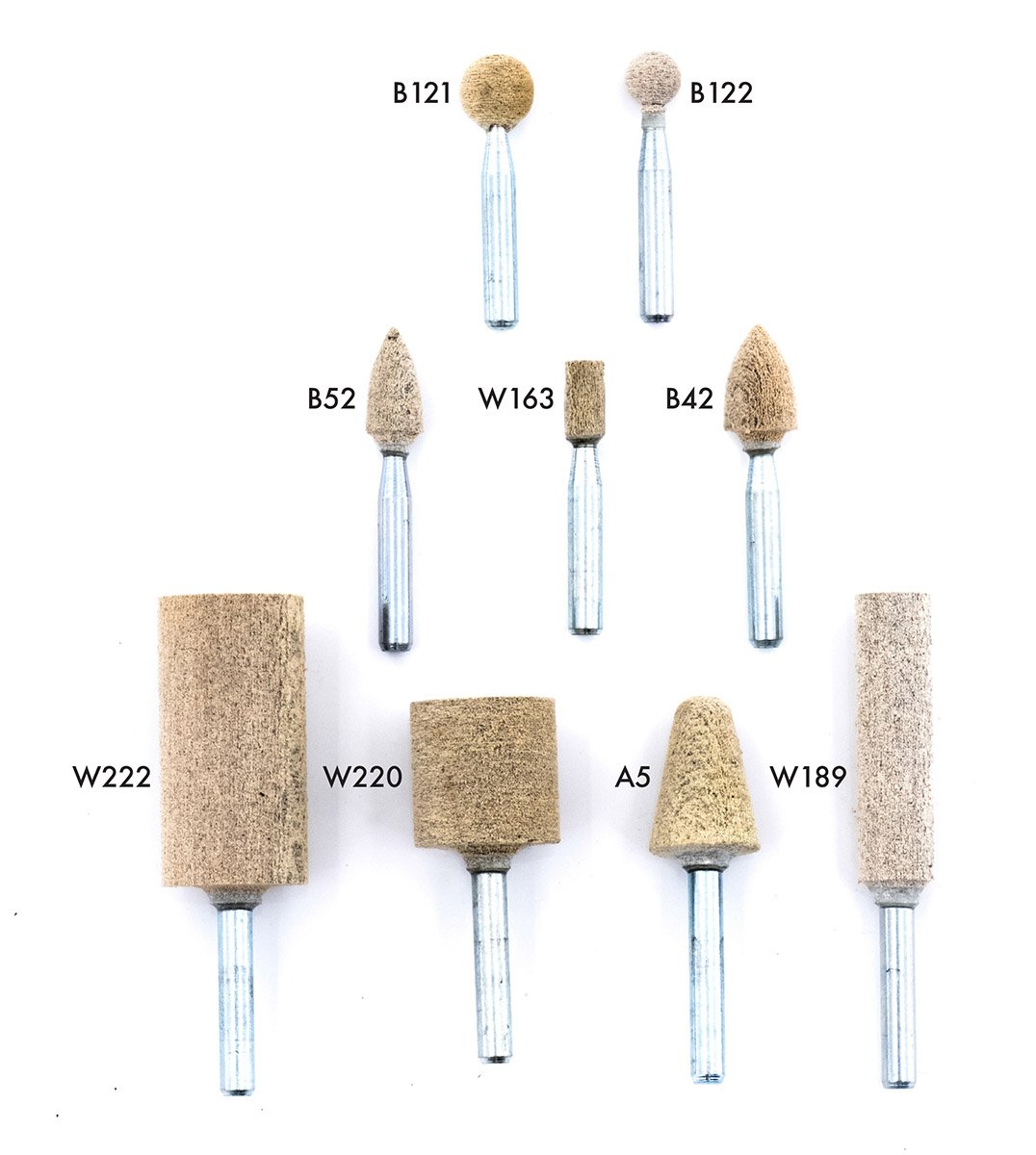

Cotton Fiber Mounted Points

A54MTX: Resin Bond for light removal/blending A80GFX: Latex Bond with finer grit for ultimate finishing Multiple layers of cotton impregnated with abrasive grain and special bonding agents allow for the coolest blending and finishing Special cotton formula minimizes loading on soft, non-ferrous metals like aluminum

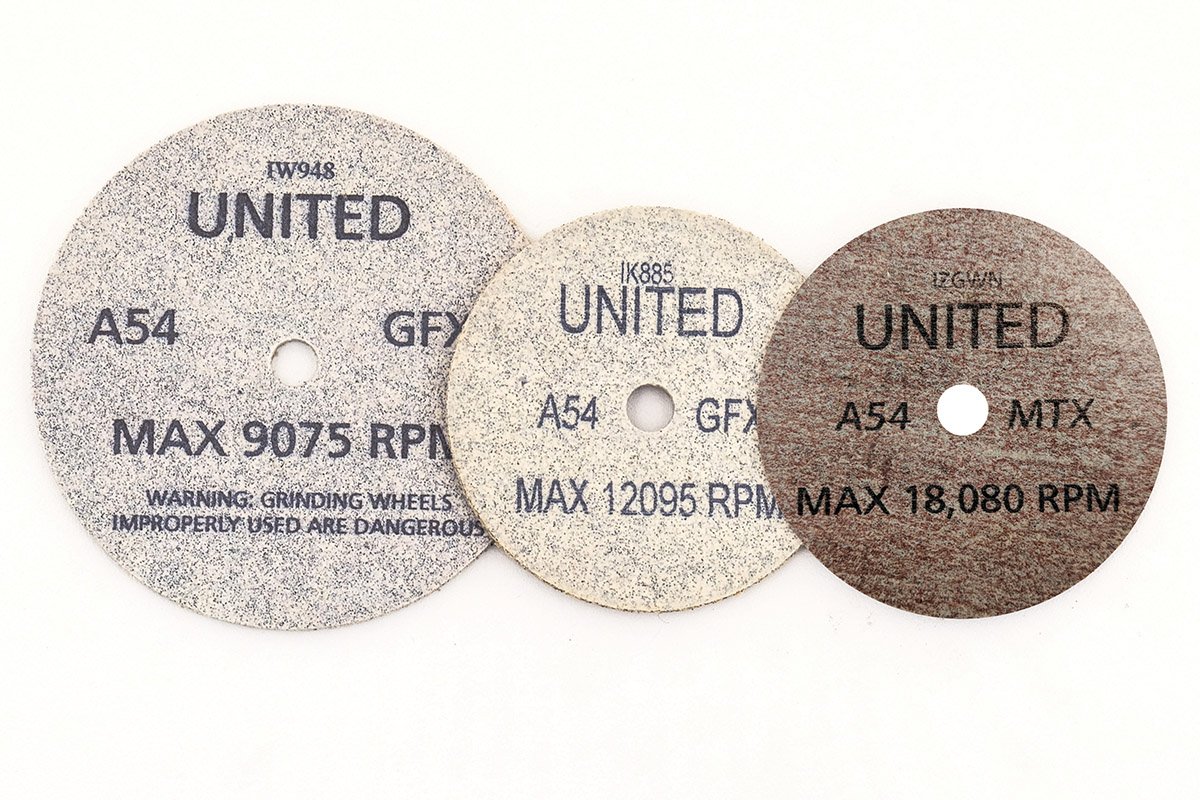

Cotton Fiber Deburring Wheels

Fine grit with higher flexibility for finishing Cotton fiber abrasive material will not smear on titanium and stainless steel Ideal for light deburring without loading or discoloration A54MTX: Resin Bond for light removal / blending A54GFX: Latex Bond with finer grit for ultimate finishing

Cotton Fiber Finishing Discs

Aluminum oxide grain Cotton fiber abrasive material will not smear on titanium and stainless steel SAIT-LOK-R™discs are made of multiple layers of cotton fiber abrasive impregnated material. These quick change discs produce a smooth finish in one step. Nylon screw threaded hub for easy mounting to the backing pad.

Subscribe

Get product news and tips straight to your inbox